We provide comprehensive waste management

Fill the order formAbout us

Geminus sp. o. o. has been on the market since 2011. We deal with the management of hazardous and non-hazardous waste, based on applicable regulations in the field of environmental protection, waste management and circular material economy.

Our primary goal is to implement, maintain and disseminate ecological and innovative solutions in the field of recycling and material recovery.

We are open to innovative solutions. Thanks to the technical background, know-how and scientific cooperation; we are constantly expanding the catalog of waste that we can process into full application market products. Each of the available waste materials is carefully analyzed in terms of re-use in the industry and we develop its physical and chemical characteristics.

We guarantee our clients reliability, efficiency and punctuality.

Geminus sp. z o. o. is a member of the Biomedical Engineering Center Cluster.

We are specialist in neutralizing following waste groups:

Expired drugs and chemical reagents

Raw materials used in the pharmaceutical industry

Sub-standard and out-of-date products

Cosmetics and raw materials for their production

Post-production wastes from paints and varnishes

Offer

Waste collection and transport

We provide:

- collection and transport for recovery or disposal of the generated waste, together with the required documentation;

- waste analysis and selection of the optimal method of their use or disposal;

- commission incineration or destruction of waste – in accordance with the client’s needs.

We operate on the basis of applicable permits, in accordance with current law (Act of December 14, 2012 on waste and Regulation of the Minister of Climate of September 11, 2020 on detailed requirements for waste storage): Decision of the Marshal of the Mazowieckie Voivodeship, number 158/20 / PZ.O (reference number PZ-OP-I.7244.18.2019) of December 9, 2020.

Our Company provides services throughout the country. We guarantee fast and timely waste collection.

Thermolysis

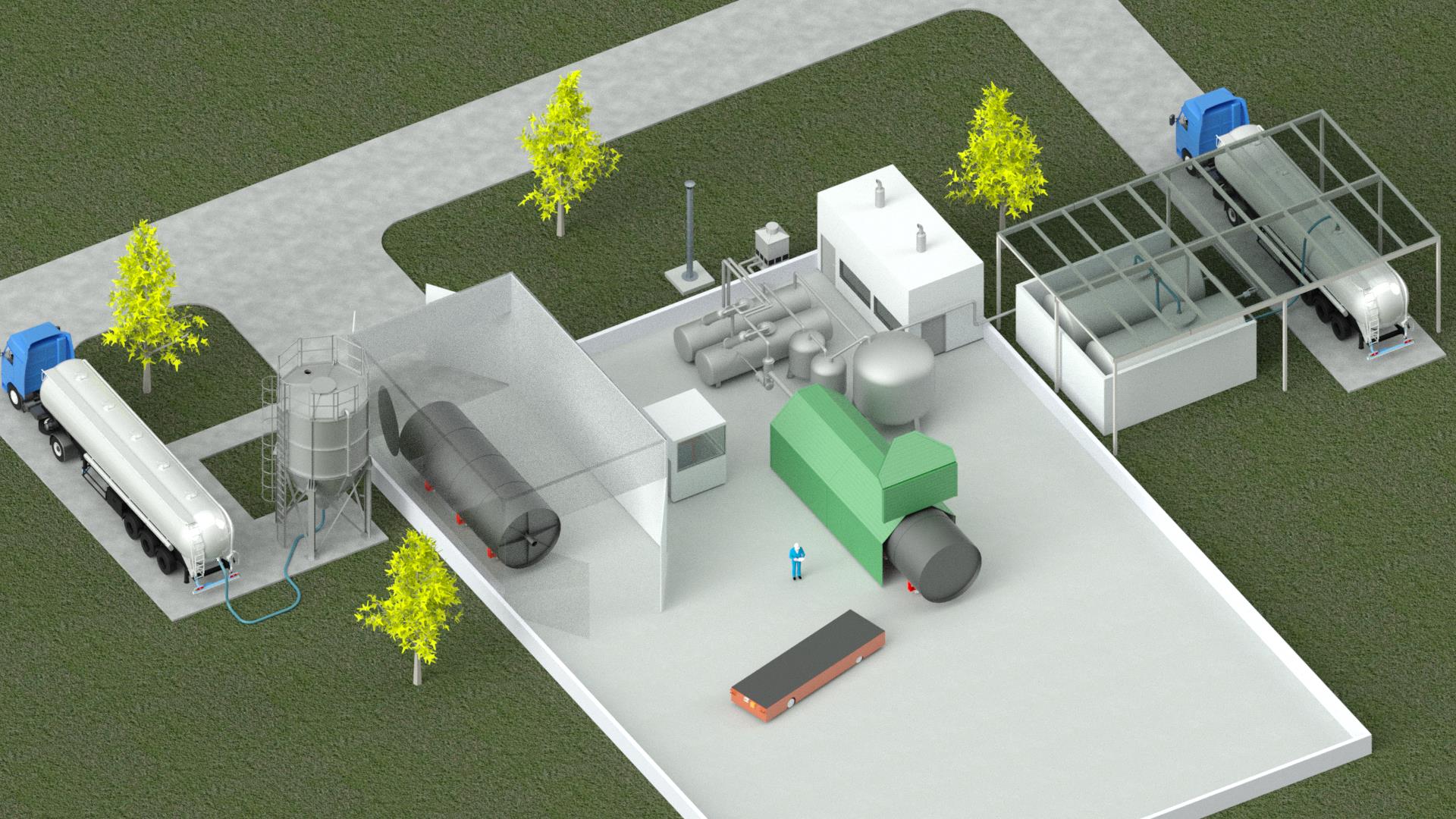

Thanks to the synergy of the environment of industry, science and technology, we have created the possibility of not only processing residual, often very problematic waste, with a huge benefit for the environment, but also making it possible to derive real profit for the producer. The thermolysis technology is a modern device, in Geminus sp. z o. o., which may confidently claim the most pro-ecological and economic form of waste recycling.

The proposed technology relies on a slow, diaphragmatic heating of waste in a rotary reactor to temperatures of 320-490C.The process is anaerobic, thanks to which there is no emission of harmful compounds such as dioxins or furans. As a result of the process, oil-gas vapors are generated, which are first separated and then condensed. Finally, we get an oil, gas and solid fraction. In our production installation, it is possible to process up to 24 Mg load per day.

Our installation is entirely electrically driven (post-thermolytic gas is converted into electricity in cogeneration modules). To ensure safety, the entire process is automatically controlled and monitored, taking into account the self-diagnosis of the device. The functionality of the device enables the introduction of large-size waste into the reactor without its prior shredding.

The technology is dedicated to the processing of organic and mixed waste, including:

- elastomers – a variety of rubber products, in particular tires, including large-size tires;

- polymers – plastic waste, polymer composites, oil and fuel filters;

- post-consumer elements of devices for the production of alternative energy sources – photovoltaic panels, wind turbine blades;

- biomass, wood waste;

- other organic waste – also cellulose, multi-material packaging, petroleum waste, textiles.

Processing products

Frakcja olejowa

Gas fraction

Solid fraction

Fertilizer lime

On the basis of the applicable decisions, we process waste with codes:

- 06 02 99

- 19 09 03

- 19 02 99

by product not containing magnesium lime fertilizer

Fertilizer lime is used for all kinds of crops in:

Where it serves, among others to de-acidify the soil, improve its structure and fertility; as well as, maintain an appropriate calcium content in the soil.

Our products – WAPNO C (type 07, decarbonised) and PUCZEK1 (type 08), meet:

- the quality requirements of the Regulation of the Minister of Economy of 8 September 2010 (Journal of Laws No. 183, item 1229), for their variety;

- requirements regarding the limit values of pollutants set out in the Regulation of the Minister of Agriculture and Rural Development of June 18, 2008 (Journal of Laws No. 119, item 765) regarding the level of cadmium and lead

which is confirmed by the research of the Institute of Soil Science and Plant Cultivation of the National Research Institute and the Research Laboratory of the Institute of New Chemical Syntheses in Puławy

We provide loading and delivery services to the farmer.

Sales office in Olsztyn (fertilizer lime): +48 505 116 528

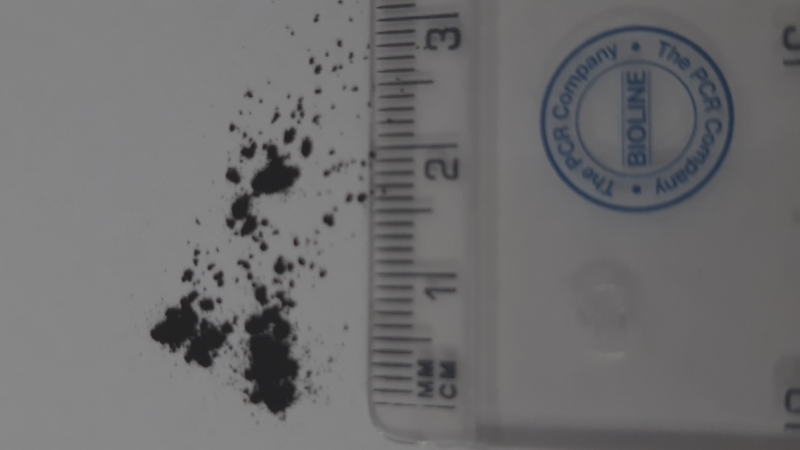

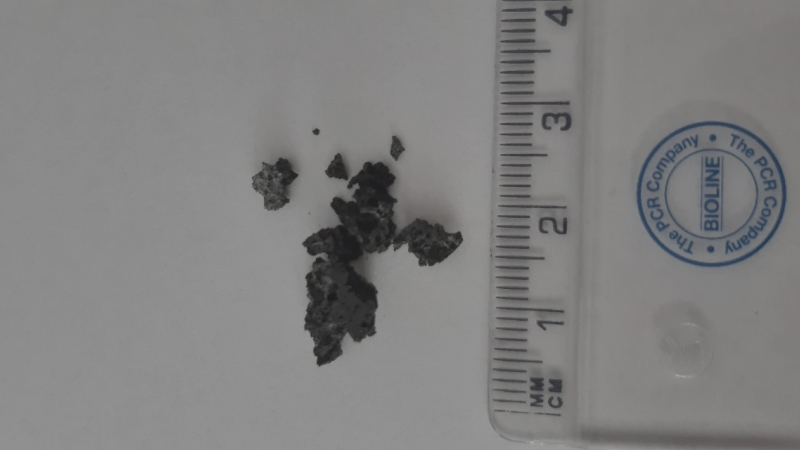

Active Carbon

One of the leading research segments is the production of activated carbon from potential waste, including MDF / chipboard.

Activated carbon is a carbon material known from the beginning of the 20th century, which, thanks to its high porosity, and thus highly developed specific surface, it has a high adsorption capacity for chemical compounds from gases and liquids. The production of activated carbon consists of two stages – carbonization and activation.

Our technology:

- maximizes the efficiency of the carbonization process by using modifications with liquid substances that intensify the flame-retardant properties of cellulose and lignites;

- is based on optimized conditions for obtaining carbon structures from a waste precursor and the development of chemically inactive intermediates into adsorptive structures with a large active surface;

- offers the possibility of modifying the obtained carbon structures for a specific application, e.g. hydrogen sulfide adsorption, purification in the spirit industry, purification columns for water and many others.

Order

Please fill in the form to send the offer.

Projects

Quality system

In 2014, we implemented the Integrated Quality and Environmental Management System according to the standards: ISO 9001: 2009 and ISO 14001: 2005. The certificates held cover the activity in the field of recovery and disposal of hazardous and non-hazardous waste.

In 2017, we adjusted the Quality and Environment Management System to the requirements of the new standards: ISO 9001: 2015 and ISO 14001: 2015 and obtained certification for the new standards.